Precast reinforced concrete

Features and operating principle

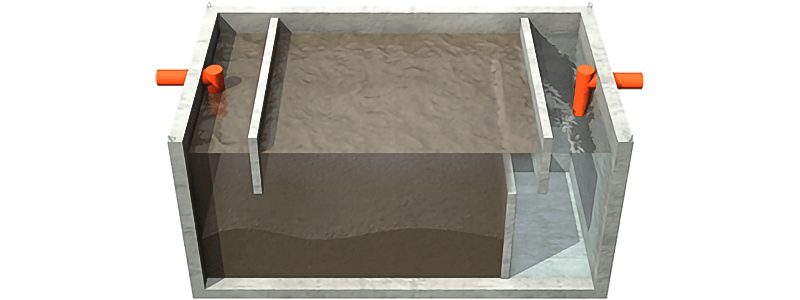

Static Desanders retain sand and other minerals which may be detrimental to the purification process. Desanders are always required in first rainwater treatment systems with relevant sand amounts, in inert storage systems, for collecting and recovering water in bathing establishments, in the fruit and vegetable sector (for washing fruits and vegetables), civil and industrial purification systems, motorway sections.

Edil Impianti Desanders can be delivered with an Automatic Sludge Extractor and Submerged Ejector Tank Cleaning System.

Edil Impianti 2 produces precast systems called gravel Deposition Tunnels generally placed at the entrance of a channel to deposit gravel or other solid materials transported by current; please contact the technical department for more information and sizing.

Supply specifications

Supply and installation of a Static Desander for burial, manufactured in SERIES DECLARED code DISS___ with external dimensions of cm. _____ x _____ x h_____ and a volume of m³_____, produced by EDIL IMPIANTI 2 S.r.l. with a UNI EN ISO 9001 and ISO 45001 management system. The desander is made of monoblock vibrated reinforced concrete, strengthened with vertical pillars and horizontal struts in stainless steel, and coated with Elastocolor, a protective elastomeric anti-crack paint, on the external concrete surfaces, which is of high permanent elasticity and high chemical resistance. The concrete is class C45/55 (RCK >55 N/mm²) in compressive strength, with internal steel reinforcements with improved bond, controlled at the factory, and a B450C type square mesh welded steel reinforcement. The unit comes with certifications for CHEMICAL RESISTANCE and FIRE REACTION (class: A1) issued by an external body according to UNI EN standards.

The static desander is supplied complete with: inlet/outlet footprints and/or boreholes; separation partition(s) for the formation of compartments.

View accessories related to the Specifications

Configure the Supply Specification with the related accessories.

Dimensioning

N.B. Separation times vary depending on the sand grain size.

ST = 5 min. for grain size around 0.20/0.30 mm >

ST = 25 min. for grain size around 0.06/0.16 mm

Static Desander Dimensions:

SV = ST x Q

where:

SV = Separation Volume

ST = Separation Time

Q = Flow rate

Accessories

Sludge Extraction and Tank Cleaning Automatic System with Submerged Ejectors and Switchboard.

Static Desander Dimensions

Data Sheet Download

Select Article Code to access the Data Sheet for the product.

| Article Code |

Volume separation Vs (mc) |

Range Q with Ts=5 min. (lt/sec) |

Range Q with Ts=25 min. (lt/sec) |

External Dimensions Desander (cm) |

Tank Weight (ql) |

Cover slab weight (ql) | ||||

| Width | Length | Height | h. 10 cm (B125) |

h. 15 cm (C250) |

h. 20 cm (D400) |

|||||

| DISS01 | 1,8 | 6,00 | 1,20 | 125 | 130 | 150 | 17,1 | 4,0 | 6,1 | 8,1 |

| DISS02 | 2,6 | 8,67 | 1,73 | 125 | 180 | 150 | 21,1 | 5,6 | 8,4 | 11,2 |

| DISS03 | 3,8 | 12,67 | 2,53 | 175 | 180 | 150 | 26,0 | 7,8 | 11,7 | 15,6 |

| DISS04 | 5,0 | 16,33 | 3,27 | 180 | 240 | 150 | 51,3 | 10,7 | 16,1 | 21,5 |

| DISS05 | 6,0 | 20,00 | 4,00 | 180 | 300 | 150 | 59,9 | 13,4 | 20,1 | 26,8 |

| DISS19 | 7,5 | 25,00 | 5,00 | 180 | 270 | 200 | 67,0 | 12,1 | 18,1 | 24,1 |

| DISS20 | 9,0 | 30,00 | 6,00 | 180 | 320 | 200 | 75,4 | 14,3 | 21,5 | 28,6 |

| DISS21 | 10,5 | 35,00 | 7,00 | 180 | 370 | 200 | 83,8 | 16,5 | 24,8 | 33,1 |

| DISS22 | 12,0 | 40,00 | 8,00 | 180 | 420 | 200 | 104,6 | 18,8 | 28,2 | 37,6 |

| DISS23 | 13,5 | 45,00 | 9,00 | 180 | 470 | 200 | 113,1 | 21,0 | 31,5 | 42,0 |

| DISS24 | 15,0 | 50,00 | 10,00 | 180 | 520 | 200 | 121,5 | 23,3 | 34,9 | 46,5 |

| DISS25 | 16,5 | 55,00 | 11,00 | 180 | 570 | 200 | 130,0 | 25,5 | 38,2 | 51,0 |

| DISS116 | 21,0 | 70,00 | 14,00 | 246 | 420 | 250 | 155,0 | 25,7 | 38,5 | 51,3 |

| DISS118 | 26,0 | 86,67 | 17,33 | 246 | 520 | 250 | 182,8 | 31,8 | 47,7 | 63,6 |

| DISS119 | 30,0 | 100,00 | 20,00 | 246 | 570 | 250 | 194,0 | 34,8 | 52,2 | 69,7 |

| DISS121 | 35,0 | 116,67 | 23,33 | 246 | 670 | 250 | 216,3 | 40,9 * | 61,4 * | 81,9 * |

| DISS123 | 40,0 | 133,33 | 26,67 | 246 | 770 | 250 | 244,1 | 47,1 * | 70,6 * | 94,1 * |

| DISS125 | 45,0 | 150,00 | 30,00 | 246 | 870 | 250 | 266,5 | 53,2 * | 79,7 * | 106,3 * |

| DISS127 | 50,0 | 166,67 | 33,33 | 246 | 970 | 250 | 294,3 | 59,3 * | 88,9 * | 118,5 * |

* Cover Slab divided into two parts

The data reported is purely indicative