Precast reinforced concrete

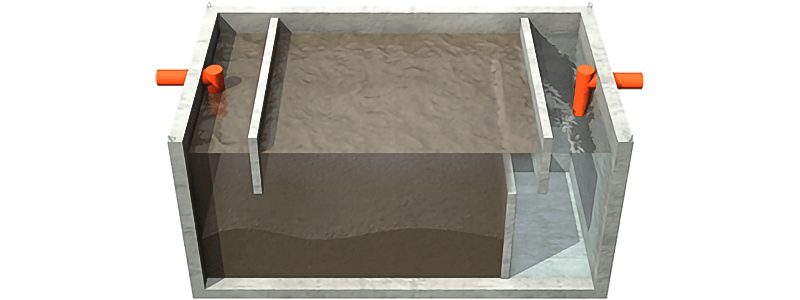

Features and operating principle

Static Desanders retain sand and other minerals which may be detrimental to the purification process. Desanders are always required in first rainwater treatment systems with relevant sand amounts, in inert storage systems, for collecting and recovering water in bathing establishments, in the fruit and vegetable sector (for washing fruits and vegetables), civil and industrial purification systems, motorway sections.

Edil Impianti Desanders can be delivered with an Automatic Sludge Extractor and Submerged Ejector Tank Cleaning System.

Edil Impianti 2 produces precast systems called gravel Deposition Tunnels generally placed at the entrance of a channel to deposit gravel or other solid materials transported by current; please contact the technical department for more information and sizing.

Supply specifications

Dimensioning

N.B. Separation times vary depending on the sand grain size.

ST = 5 min. for grain size around 0.20/0.30 mm >

ST = 25 min. for grain size around 0.06/0.16 mm

Static Desander Dimensions:

SV = ST x Q

where:

SV = Separation Volume

ST = Separation Time

Q = Flow rate

Accessories

Sludge Extraction and Tank Cleaning Automatic System with Submerged Ejectors and Switchboard.

Static Desander Dimensions

Data Sheet Download

Filter by Total Volume and Height to see the Results.

| Article Code |

Total volume (mc) |

Tank external dimensions (cm) | Tank Weight (ql) |

Inspection 60x60 N. | ||

| Width | Length | Height | ||||

| VACM01H100 | 1,2 | 125 | 130 | 100 | 11,8 | 1 |

| VACM02H100 | 1,7 | 125 | 180 | 100 | 14,9 | 1 |

| VACM03H100 | 2,5 | 180 | 180 | 100 | 29,1 | 1 |

| VACM04H100 | 2,7 | 180 | 220 | 100 | 33,8 | 2 |

| VACM05H100 | 3,0 | 180 | 240 | 100 | 36,1 | 2 |

| VACM06H100 | 3,5 | 180 | 270 | 100 | 39,6 | 2 |

| VACM07H100 | 3,7 | 180 | 300 | 100 | 43,1 | 2 |

| VACM08H100 | 4,0 | 180 | 320 | 100 | 45,4 | 2 |

| VACM09H100 | 5,0 | 180 | 370 | 100 | 51,2 | 2 |

| VACM14H100 | 4,0 | 246 | 220 | 100 | 43,3 | 2 |

| VACM15H100 | 5,0 | 246 | 270 | 100 | 50,5 | 2 |

| VACM16H100 | 6,0 | 246 | 320 | 100 | 57,6 | 2 |

| VACM17H100 | 7,0 | 246 | 370 | 100 | 64,8 | 2 |

| VACM18H100 | 7,5 | 246 | 420 | 100 | 71,9 | 2 |

| VACM19H100 | 8,5 | 246 | 470 | 100 | 81,0 | 2 |

| VACM20H100 | 9,5 | 246 | 520 | 100 | 88,1 | 2 |

| VACM21H100 | 10,5 | 246 | 570 | 100 | 95,3 | 2 |

| VACM22H100 | 11,5 | 246 | 620 | 100 | 102,4 | 2 |

| VACM23H100 | 12,5 | 246 | 670 | 100 | 109,6 | 2 |

| VACM24H100 | 13,0 | 246 | 720 | 100 | 118,7 | 2 |

| VACM25H100 | 14,0 | 246 | 770 | 100 | 125,8 | 2 |

| VACM26H100 | 15,0 | 246 | 820 | 100 | 133,0 | 2 |

| VACM27H100 | 16,0 | 246 | 870 | 100 | 140,1 | 2 |

| VACM28H100 | 17,0 | 246 | 920 | 100 | 147,3 | 2 |

| VACM29H100 | 18,0 | 246 | 970 | 100 | 156,4 | 2 |

| VACM30H100 | 19,0 | 246 | 1020 | 100 | 163,5 | 2 |

| VACM31H100 | 20,0 | 246 | 1070 | 100 | 170,7 | 2 |

| VACM32H100 | 20,5 | 246 | 1120 | 100 | 177,8 | 2 |

| VACM33H100 | 21,5 | 246 | 1170 | 100 | 186,9 | 2 |

| VACM34H100 | 22,5 | 246 | 1220 | 100 | 194,0 | 2 |

| VACM35H100 | 23,5 | 246 | 1270 | 100 | 201,2 | 2 |

| VACM36H100 | 24,5 | 246 | 1320 | 100 | 208,3 | 2 |