Industrial Wastewater Treatment

Car Wash treatment Systems

Somethings

second subtitle

Features and operating principle

Membrane Biological Reactors MBR are derived from the coupling of traditional suspended biomass processes with filtration processes on microporous or ultra-porous membranes, depending on the nominal pore size.

The greatest advantages of this technology are to be found in the possibility of eliminating the sedimentation unit downstream of the biological compartment and all the management and operational constraints associated with it.

Replacing the sedimentation compartment with a membrane filtration compartment involves:

- a considerable reduction in the floor space of the sewage treatment plant due to both the disappearance of the settling tank and the increase in the concentration of suspended solids in the biological reactor;

- the possibility of managing the biological process in a totally independent way from hydraulic load fluctuations (cell residence time and hydraulic retention time are completely disconnected from each other);

- the decrease in superfluid sludge, associated with higher mud age values;

- The elimination of sludge sedimentation problems normally encountered in conventional activated sludge plants;

- the significant improvement of the effluent quality characteristics, compatible with the potential agricultural reuse of purified water.

Supply specifications

Supply and installation of a Modular Car Wash treatment Systems produced in DECLARED SERIES code SBAF__MOD for discharges into surface waters, composed of Prefabricated Buried Tanks produced by EDIL IMPIANTI 2 S.r.l. with a UNI EN ISO 9001 and ISO 45001 management system, made of monoblock Vibrated Reinforced Concrete, reinforced with vertical pillars and horizontal stainless steel struts, with Elastocolor protective anti-cracking elastomeric paint on the external concrete walls with high permanent elasticity and high chemical resistance, concrete in compression resistance class C45/55 (RCK >55 N/mm²), internal steel reinforcements with improved adherence controlled at the factory and B450C type square-mesh electro-welded wire mesh, accompanied by CHEMICAL RESISTANCE and REACTION TO FIRE (class: A1) certificates issued by an external body according to UNI EN standards.

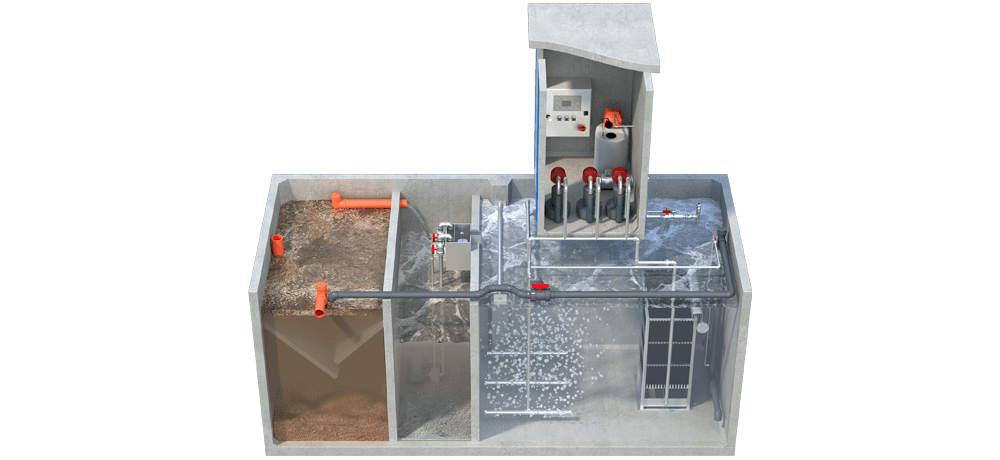

The Modular Car Wash Purifier is composed of 6 compartments: Sand Separator, Oil Separator, Biofiltration Reactor, Sludge Accumulation, Clarified Water Accumulation, and Technical Compartment.

The various phases (sand separation, oil separation, biofiltration, sludge accumulation, clarified water accumulation) are in turn supplied complete with: inlet/outlet holes, phase connection pipes, ringed PVC fittings, Refill type coalescence filtration, 90mm diameter PVC channel complete with PVC ball valve, lower and upper grid for closing the filling bodies, spherical bulk filling bodies in isotactic polypropylene with a specific surface area of approximately 450-550 sq.m./cu.m., air delivery manifold, 40mm diameter perforated PVC pipes with PVC ball valve, no. 2 Air-lifts in 63mm diameter PVC each complete with 20mm diameter PVC air delivery pipe, 20mm diameter PVC ball valve, 90mm diameter clarified discharge PVC pipe with PVC ball valve, stainless steel and PVC brackets/collars for fixing pipes.

The Technical Compartment is supplied complete with: AISI 304 stainless steel door with lock, no.2 ventilation grilles, light point (on request), no.2 holes, no.1 side channel blower, 200 mbar pressure, complete with filter, silencer, anti-vibration hose and electrical panel with PLC logic in polycarbonate complete with accessories for automatic blower control, contactor, thermal protection relay, pause-work programmer, man-0-aut selector, block and operation indicator lights.

View accessories related to the Specifications

Configure the Supply Specification with the related accessories.