Industrial Wastewater Treatment

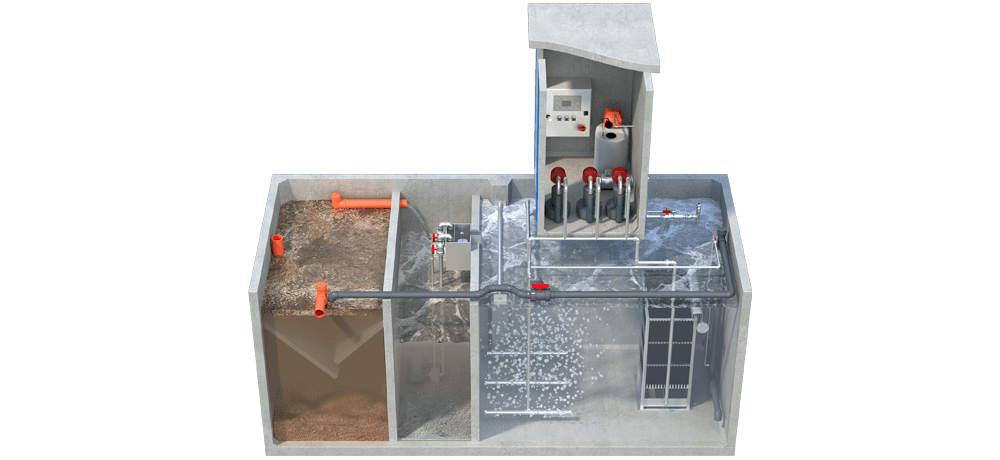

MBR System (Membrane Biological Reactor)

Biological Purification with Activated Sludge and Ultrafiltration of Sludge

using Membranes instead of Traditional Clarifiers

Features and operating principle

Membrane Biological Reactors MBR are derived from the coupling of traditional suspended biomass processes with filtration processes on microporous or ultra-porous membranes, depending on the nominal pore size.

The greatest advantages of this technology are to be found in the possibility of eliminating the sedimentation unit downstream of the biological compartment and all the management and operational constraints associated with it.

Replacing the sedimentation compartment with a membrane filtration compartment involves:

- a considerable reduction in the floor space of the sewage treatment plant due to both the disappearance of the settling tank and the increase in the concentration of suspended solids in the biological reactor;

- the possibility of managing the biological process in a totally independent way from hydraulic load fluctuations (cell residence time and hydraulic retention time are completely disconnected from each other);

- the decrease in superfluid sludge, associated with higher mud age values;

- The elimination of sludge sedimentation problems normally encountered in conventional activated sludge plants;

- the significant improvement of the effluent quality characteristics, compatible with the potential agricultural reuse of purified water.

Supply specifications

Supply and installation of MBR (Membrane Biological Reactor) system produced in DECLARED SERIES, composed of Precast Tanks to installed underground produced by EDIL IMPIANTI 2 S.r.l. with management system UNI EN ISO 9001 and ISO 45001, made of monoblock vibrated concrete, reinforced with vertical pillars and stainless steel horizontal beams, with Elastocolor elastomeric anti-cracking protective paint on the outer walls in permanent high elasticity and high chemical resistance concrete, concrete in class of resistance to compression C45/55 (RCK >55 N/mm 2), internal steel reinforcement with improved adhesion controlled in the factory and welded mesh type B450C, accompanied by certificates CHEMICAL RESISTANCE and REACTION TO FIRE (class: A1) issued by an external body according to UNI EN standards.

The MBR system consists of:

- Imhoff tank (primary sedimentation - anaerobic digestion) in accordance with UNI EN 12566-1 and UNI EN 12566-3 standards complete with inlet and outlet, PVC ring fittings, stainless steel housing AISI 304 or similar, vents, internal hoppers perfectly sealed for clear separation of the sedimentation/digestion chambers made of reinforced concrete;

- Lifting/ Complete accumulation of inlet, PVC fittings with rings, n.1 submersible electric pump brand Calpeda or similar (with the following minimum technical characteristics: 2-pole induction motor, 50 Hz, 230/400 V power supply, class F insulation, IP protection X8, power 0.55 kW, absorption 2.6/1.5 A, Q= 12 mc/h - H= 6 mt, vortex impeller), pvc pipe, special connections, control valves, telescopic system for the adjustment of the supply flow chamber oxidizer made of stainless steel AISI 304;

- Oxidation (aerobic biological treatment) complete of inlet and outlet, any ring pvc fittings, porous microbubble diffusers with EPDM membrane, downspouts and air distribution manifold made of stainless steel AISI 304 complete with control valve carried on each individual downspout, n.1 side channel blower brand FPZ or similar having technical characteristics as from the technical report; n.1 air-lift pump for mud recirculation made of pvc complete with special fittings and fixing brackets. MBR membrane module/s consisting of an "element" block and an aeration block.

The elements are distributed in series and equally spaced, each having flat membranes that adhere to the two sides of an ABS support panel. Each element is connected to the permeate collector by means of a polyurethane tube. The ventilation block consists of fine bubble diffusers for air supply. The system is complete with n.1 flow quantity control device, such as a flow meter and an automatic control valve, of n.1 suction pump equipped with inverters installed on the line to control the permeate flow quantity, of n. 1 pressure difference measurement and calculation system able to determine the trans-membrane pressure (TMP) complete with n.2 pressure sensors programmed with logic plc or differential pressure switch, n.1 level indicator to be installed in the tank of submerged membranes to check the liquid level and to calculate the TMP through plc logic, n.1 special post-suction siphon system, plastic tubing kit and or stainless steel AISI 304, Acid dosing kit for membrane cleaning consisting of: n.1 electronic diaphragm dosing pump brand Doseuro or similar having technical characteristics as in the technical report, Self-supporting polyethylene cylindrical tank with a minimum capacity of 100 lt. and suction system on rod complete with end filter; - Technical Room made withc.a.v. complete with front door to 1 Door type EI2 60 according to UNI EN 1634-1 from cm.90x205, with paint color RAL9002, with standard lock complete of grates in order to guarantee a minimum internal ventilation and n.1 electrical panel with programmable plc logic for the control of various utilities.

Guarantee of Treatment:

D.Lgs 152/06 Part Three, Annex 5, Table 3 "Discharge into Surface Water", provided that the qualitative and dimensional values of inflow in the treatment itself are respected and guaranteed.

View accessories related to the Specifications

Configure the Supply Specification with the related accessories.